Wood

Laser cutting machines are divided into two types based upon laser sources: fiber laser machines and CO2 machine.

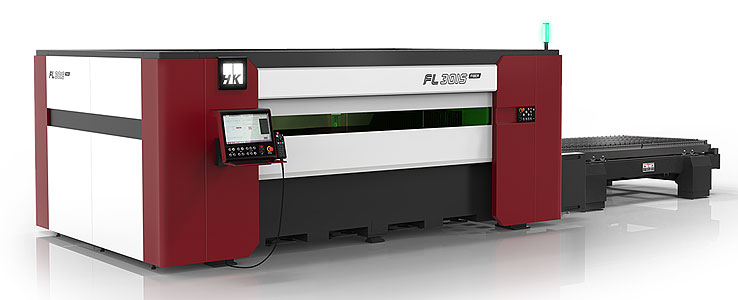

Send your design to laser. You can choose the parameters of the laser or a preset material setting in GSS Machinery's vast database.